ou may ask, what are bulk materials? Bulk materials are dry and solid things. They are found in big amounts and are not packed. Some examples are grains, coal, sand, minerals, and fertilizer. You often see these goods in large piles or containers. Bulk goods are very important in daily life and big industries. For example, farming, mining, and building need to move and use these materials well. When you know what bulk materials are, you can see how they help supply chains work and help the economy grow.

Bulk materials are dry and solid things like grains, coal, and sand. They are moved in big amounts without any packaging.

It is important to know particle size, density, and texture. This helps pick the right equipment. It also helps stop dust, clogs, and machine damage.

Bulk materials help many industries like mining, construction, food, and power. They make daily life and the economy work better.

Good handling, storage, and transport systems keep bulk materials safe. They also cut down on waste and save money.

Safety and keeping things clean are very important. This protects workers and keeps bulk materials clean and useful.

If you wonder, “what are bulk materials?”, you want a simple answer. Bulk materials are dry and solid things. People handle them in big amounts. They can be powder, grains, or lumps. You often see them in huge piles or moved in bulk. They are not packed in small boxes or bags. Grains, coal, minerals, and sand are some examples. Many industries use bulk materials. They are easy to move and use.

It is important to know how bulk materials are not like nanomaterials. Here are some main differences:

Nanomaterials are very tiny, less than 100 nanometers. Bulk materials are much bigger.

Nanoparticles act special because they are so small. Bulk materials stay the same no matter their size.

Nanomaterials can change how they melt or their surface energy. Bulk goods do not change these things.

The shape and size of nanoparticles matter a lot. Bulk materials act the same even if their size changes.

When you work with bulk materials, you care about moving lots of them. You do not need to think about tiny details like with nanomaterials.

You see bulk materials all the time. These goods are important for many jobs and daily life. Here is a table with examples and why they matter:

| Bulk Material Category | Examples of Bulk Materials | Volume Significance / Market Share |

|---|---|---|

| Major Bulks | Iron ore, coal, grain, bauxite, phosphate rock | Account for approximately 67% to 70% of dry bulk shipping market |

| Minor Bulks | Steel, timber, fertilizers, cement, sugar | Make up the remaining 30% of the dry bulk shipping market |

Iron ore and coal are found in huge amounts. These goods help build things, make energy, and grow food. Grains, fertilizer, and cement are also common bulk goods.

Different jobs need different bulk materials. Here is a quick table to show how they are used:

| Industry | Bulk Materials Used | Description Summary |

|---|---|---|

| Metals & Mining | Metals and minerals (iron ores, rare earths) | You dig up metals and minerals, make ores, and clean metals. Iron ores and precious metals are important. |

| Coal Operations | Coal (thermal and metallurgical) | You mine coal and make coal products. Coking coal is needed for steel. |

| Iron & Steel Producers | Iron ore, coal (coking coal) | You make iron and steel with iron ore and coal in furnaces. |

| Construction Materials | Bulk minerals (cement, aggregates, sand, gravel) | You use minerals, sand, and gravel to make building materials. |

| Food, Chemical, Pharmaceutical, Power Generation | Grains, coal (for electricity) | You use grains and coal for food and making power. |

Bulk goods are everywhere. You need them to build roads, make steel, grow food, and make electricity. When you learn about bulk materials, you see how they help shape your world.

Particle size is very important when you work with bulk materials. Small particles can float in the air and make dust. This dust can block machines and cause problems. Big particles move more easily but can damage machines and make noise. If you have both big and small particles, they can split apart when moved. This makes mixing and measuring less accurate. Knowing the particle size helps you pick the right equipment and stop problems like clogs or wasted space.

Small particles float and make dust that blocks machines.

Small particles can stick together and block bins.

Big particles move better but wear out machines and are noisy.

Mixed sizes can split up, so mixing is not even.

Good particle size data helps you design better systems and stop stoppages.

You can check particle size in different ways. Here is a table with some common methods:

| Method Type | Standard Number | Description |

|---|---|---|

| Sieving | ASTM C136/C136M | Sieve Analysis of Fine and Coarse Aggregates |

| Laser Diffraction | ISO 13320 | Particle Size Analysis — Laser Diffraction Methods |

| Microscopy | USP <776> | Optical Microscopy (Particle Size Characterization) |

| Electrical Sensing Zone | ASTM C690 | Particle Size by Electrical Sensing Zone Technique |

| Image Analysis | ISO 13322-1 | Particle Size Analysis — Image Analysis Methods |

Tip: Using more than one way to measure gives you better particle size data for bulk materials.

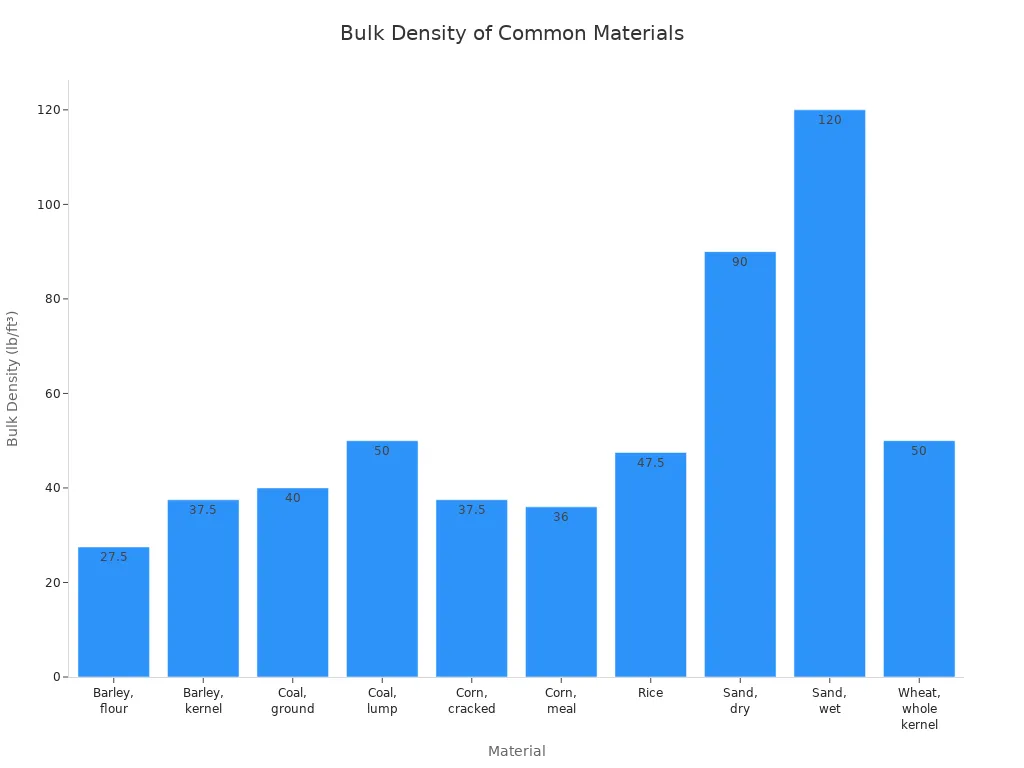

Density changes how bulk materials move. Bulk density means how much mass is in the space, including the gaps. Materials with high bulk density move better because gravity helps them. Low-density materials stick together and do not move well. You might see problems like arching or rat-holing in bins.

High bulk density means better flow and less sticking.

Low bulk density means more friction and poor flow.

The Hausner ratio helps you see if a powder will flow well. A high ratio means it will not flow well.

Agglomeration can make bulk density higher and make particles rounder. This helps bulk materials move better and stops problems in hoppers and silos.

Here is a table with bulk density ranges for some common materials:

| Material | Typical Bulk Density Range (lb/ft³) |

|---|---|

| Sand, dry | 80 – 100 |

| Coal, lump | 45 – 55 |

| Corn, cracked | 35 – 40 |

| Rice | 45 – 50 |

| Wheat, whole kernel | 45 – 55 |

Texture changes how much bulk materials wear down machines. If the material has sharp edges or rough surfaces, it can scratch and cut machines. How fast and at what angle the particles hit the equipment also matters. Fast, sharp particles do more damage. Materials like silica sand, alumina, and cement clinker are very abrasive. You need special machines to handle them safely.

| Abrasive Material | Characteristics and Challenges | Management Strategies |

|---|---|---|

| Silica Sand | Very abrasive; wears out machines; makes dangerous dust | Use strong equipment; control dust; keep workers safe |

| Alumina | Abrasive powder; damages air systems | Use special parts that resist wear |

| Cement Clinker | Very abrasive lumps; damages conveyors and kilns | Use tough equipment; use parts that resist wear |

| Zircon Sand | Heavy; odd shape; abrasive | Use special equipment to lower wear |

Note: Always check the texture and abrasiveness before picking equipment. This helps you avoid expensive repairs and keeps your process safe.

Bulk materials are very important for many industries. They help factories work and make things people use every day. Iron ore, coal, and grain travel around the world on big ships. Dry bulk goods like coal, iron ore, and grain are 36% of all goods shipped by sea. This shows they are worth a lot of money. In 2019, all shipping trade, including bulk, was over 14 trillion dollars.

Here is a table that shows how industries use bulk materials:

| Industry Category | Examples of Bulk Materials Handled | Why They Matter |

|---|---|---|

| Food Industries | Wheat, flour, sugar, corn, coffee beans | Needed for steady food production |

| Breweries | Malt, grain | Key for brewing beer |

| Polymer Industries | Polymer pellets, powders | Used in making plastics |

| Pharmaceuticals | Chemical powders | Needed for medicine production |

| Chemical & Petrochemical | Various powders and solids | Support chemical processing |

| Minerals & Mining | Raw minerals | Fuel mining and refining |

| Fertilizers | Chemical powders, granules | Support large-scale farming |

| Paints | Pigments, powders | Needed for color and coatings |

Bulk materials are used at every step in making products. Machines move these materials fast and safely. This helps factories make more things and waste less. Using bulk materials saves money and helps companies work better.

Note: Many industries need a steady flow of bulk goods to keep making products and meet quality rules.

Bulk materials are also part of your daily life. You buy rice, beans, flour, or sugar in big containers. Some stores let you bring your own bags or jars to fill up. This means less packaging is used. It also helps stop food waste, which can be up to 40% of all food made. When you buy only what you need, you save money and waste less.

You also use bulk materials that are not food. Shampoo, cleaning products, and toilet paper can come in big packs. Cities pick up big trash like old furniture and appliances. Dangerous bulk items, like old paint or batteries, are collected at special times to keep people safe.

Here are some ways bulk materials are part of your life:

You buy food like coffee, pasta, nuts, and spices in bulk to use less packaging.

You refill cleaning and personal care products to make less waste.

You help the planet by using your own containers when shopping for bulk goods.

Tip: Buying bulk goods helps you save money, make less trash, and keep the earth clean.

Bulk material handling systems help move, store, and process lots of bulk materials. These systems make work faster and safer. Most systems have a few main parts:

Unloading stations let bulk materials enter the system.

Conveying systems move bulk materials from place to place.

Storage units keep bulk materials safe until needed.

Batching equipment measures and mixes materials.

Filling or packaging stations get bulk materials ready for shipping.

Conveying systems are used often. Pneumatic conveying systems use air to move powdery bulk materials in pipes. These systems are clean and fast. They work well for grains, powders, and other dry bulk. Pneumatic conveying can move materials far inside a plant. Automated handling systems, like robotic loaders and smart conveyors, work quickly and make fewer mistakes. They help workers stay safe and let them do other jobs.

Tip: Automated bulk material handling systems save time, cut waste, and make work safer.

You need good storage methods to keep bulk materials safe and fresh. The best way depends on the type of bulk material. For grains, use grain elevators and airtight silos. These keep out bugs and control temperature and humidity. For minerals and ores, use stockpiles, stackers, and reclaimers. These store large amounts and make it easy to get materials.

Some best ways to store bulk materials are:

Use sealed silos or bins to stop contamination.

Check sealing systems often.

Add dust collectors and ventilation for clean air.

Clean storage units regularly.

Watch temperature and humidity with sensors.

Design storage for easy flow to stop blockages.

Keep batches apart to avoid mixing.

Use liners or coatings for extra protection.

Teach workers safe handling.

Check storage units often for damage or pests.

Pneumatic conveying systems help fill and empty storage units quickly. You can use these systems to move bulk materials between silos, hoppers, and processing areas. Pneumatic conveying keeps things clean and lowers spoilage risk.

You move bulk materials far using a few main ways. Rail transport carries lots of bulk, like coal or grain, across land. Ocean transport is best for shipping bulk materials around the world. Ships carry huge amounts of dry bulk, like minerals, or liquid bulk, like oil. Pipelines are good for moving liquids and gases, like oil and natural gas, far away.

Rail transport is good for raw materials and bulk cargo.

Ocean transport is cheap and works worldwide.

Pipelines move liquids and gases all the time.

Trucks move bulk for short or medium trips.

Air transport is rare for bulk because it costs a lot.

Bulk material conveying systems, especially pneumatic conveying, help load and unload bulk from trains, ships, and trucks. These systems make it easy to move powdery bulk materials without spills. Bulk shipping costs less than shipping packaged goods. You save money by moving more at once and using less packaging.

| Aspect | Bulk Materials Transportation | Packaged Goods Transportation |

|---|---|---|

| Cost per Unit | Lower because you move more at once | Higher because it needs special handling |

| Handling Requirements | Simple, saves money | Needs special equipment and controls |

| Infrastructure | Needs special bulk systems | More expensive logistics |

| Delivery Speed | Flexible | Often faster, especially for perishables |

| Risk of Damage | Lower, less handling | Higher, more sensitive to damage |

Note: Using the right bulk material handling and conveying systems helps you move bulk safely, quickly, and for less money.

Safety is very important when working with bulk materials. There are many ways you or your team can get hurt. You could trip over piles or get injured if things are not stored safely. Dust from bulk materials can start fires or even explode. Sometimes, pests or rodents hide in the stored materials and can make people sick. Machines might break or get too full, which can cause accidents. Doing the same task over and over can hurt your muscles.

Some main safety risks are:

Getting hurt by tripping or falling materials

Health issues from pests and rodents

Fires or explosions from dust

Machines breaking or getting overloaded

Muscle injuries from lifting or repeating tasks

You should always wear safety gear like gloves, goggles, and boots with hard toes. Check machines often and make sure everyone knows how to use them. Practice what to do if there is a spill or leak. Look for dangers before you start working. If everyone cares about safety, there will be fewer accidents.

Contamination is a big problem with bulk materials. Dust, dirt, and water can get into materials, especially outside. Flexible parts between machines can let in unwanted stuff. If you do not stop contamination, you might have to recall products. This can cost a lot of money and hurt your business. Dirty food or chemicals can make people sick and get your company in trouble.

Contamination can happen in these ways:

Dust and dirt in the air getting into materials

Bad seals between machines

Mixing up different materials by mistake

To stop contamination, use closed containers and equipment. Keep storage places clean and dry. Use dust collectors and covers on bins. Clean all tools and machines often. Keep dangerous or allergy-causing materials apart. Good training and new tools help you find and stop contamination early.

Efficiency means moving and storing bulk materials with less waste and cost. You need to pick the right system, like pneumatic conveying, for the material’s size and flow. A good layout saves space and makes fixing things easier. Robots and smart sensors help you watch how materials move and find problems fast. Pneumatic conveying moves powders and grains quickly and safely, so people do not have to do as much work.

Important things for efficient bulk handling are:

Knowing about the material’s size and how it flows

Using the best system for each job

Making the layout safe and easy to use

Cutting out extra steps and saving time

New technology, like smart devices and AI, helps you watch your work and know when to fix machines. Green choices, like electric conveyors, use less energy and help the planet. When you work on efficiency, you make things safer, save money, and keep everything running well.

You now know that bulk materials are dry, solid substances moved in large amounts. You see them in many industries and in your daily life. These materials help build cities, grow food, and power factories. Handling bulk materials takes skill and the right tools. When you understand their value, you can see how they shape the world around you.

Remember: Bulk materials are everywhere. You play a part in how they are used and managed.

There are two main types of bulk materials. Dry bulk includes things like grains, coal, and sand. Liquid bulk means things like oil and chemicals. Each type needs special ways to handle and store them.

Industries like bulk materials because they are easy to move and store. Using bulk materials saves both money and time. You also use less packaging, which helps the planet. This makes work faster and better for the environment.

You should use sealed containers to keep materials safe. Clean storage areas often to stop dirt and pests. Train workers well so they know how to keep things clean.

Tip: Always look for leaks or damage in storage units.

You need things like conveyors, silos, hoppers, and pneumatic systems. These tools help you move, store, and measure bulk materials safely. The best equipment depends on the size and texture of the material.

Yes, you can recycle many bulk materials. Metals, glass, and some plastics are easy to recycle. Recycling saves resources and helps the earth.

| Material | Can You Recycle? |

|---|---|

| Metals | ✅ |

| Glass | ✅ |

| Plastics | ✅ |

| Coal | ❌ |

| Grains | ❌ |